We are the UK’s leading supplier of collaborative robots

![]()

![]()

![]()

![]()

A new generation of autonomous mobile robots (AMRs) are changing the way businesses move materials inside their facilities – and MiR is leading the change. We offer the full fleet of flexible and easy-to-program MiR collaborative mobile robots, designed for the transportation of both heavy and light loads.

Warehouse automation can bring many benefits including:

Two of the AMRs within this range (MiR600 and MiR1350) are the first AMR robots in the market to receive an IP52 rating, which means they can be used in more challenging environments.

Need flexibility? User-friendly MiR robots enable you to adapt to changing market demands, new products, and new production flows. All robots can be mounted with MiRGo customised top modules such as:

Logistics and warehouse automation often leads to robots having to navigate around busy environments, making safety paramount.

All MiR mobile robots are easily operated through a smartphone, tablet or PC. MiR’s integral technology enables the robots to either “identify” their own driving area and surroundings or import 3D drawings of the building layout.

Designed for driving safely in industrial environments, the mobile robots also have built-in multi-sensor systems and cameras that feeds data into an advanced planning algorithm, which lets the MiR robot know where to drive and if it should adjust its path or make a safe and immediate stop to avoid collisions.

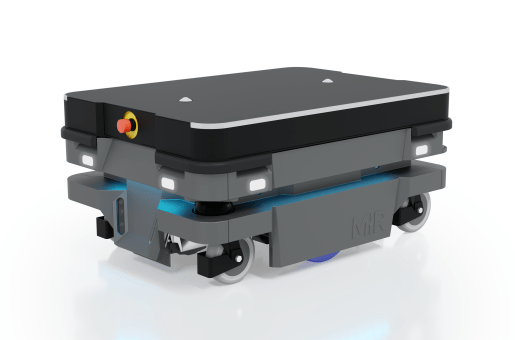

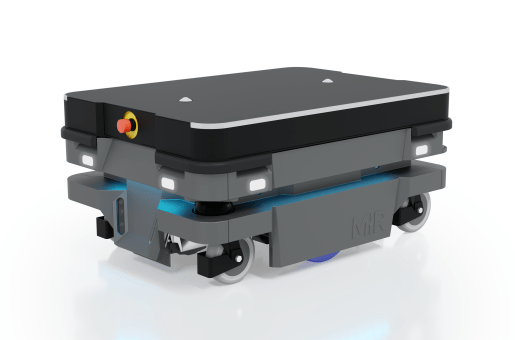

The MiR250 sets new standards for internal logistics being faster, safer and more agile than any other solution in the same category on the market. This AMR can navigate smoothly and efficiently in dynamic environments and even drive through doors as narrow as 80cm.

The MiR250 Shelf Carrier is a standard top module which attaches to the MiR250 robot to efficiently transport and deliver shelves, carts and other applications throughout your facility. The shelf carrier also acts as a anchoring device which makes it possible to lock carts and move them.

The MiR250 Hook autonomously picks up and unloads carts and is ideal for a wide range of towing jobs, such as efficiently moving heavy products between locations in a manufacturing facility or warehouse.

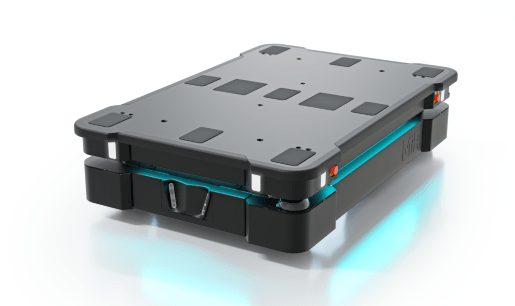

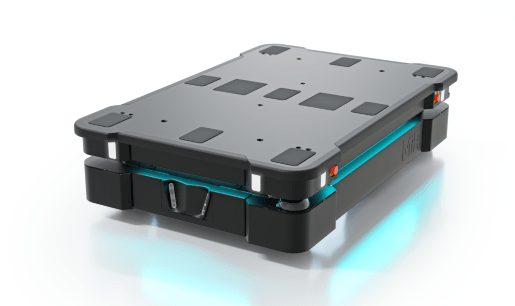

One of the first IP52 rated AMRs on the market, the MiR600 has an increased ability to withstand dust particles and fluids, resulting in it being used in more environments. For example, it can drive close to open gates or other places where there is exposure to water drops and dirt.

Along with the MiR600, the MiR1350 is also the first IP52 rated AMR on the market and the most powerful AMR to date, enabling you to efficiently move very heavy loads and pallets automatically.

The MiR1350 is compliant with the highest available safety standards – ISO3691-4, making it superior to other AMRs on the market.