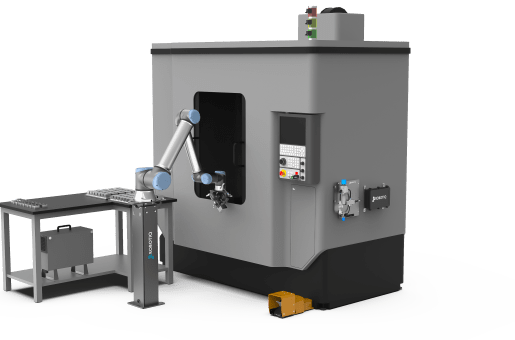

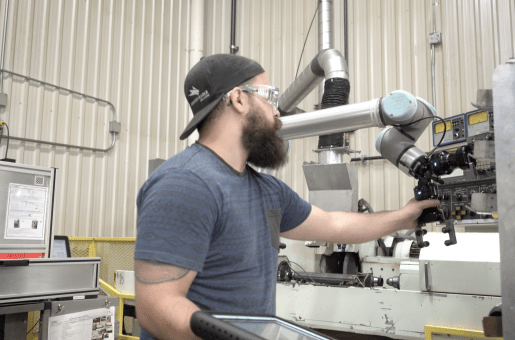

Automated Machine Tending

It’s now easier than ever to automate CNC machine tending with industrial and collaborative robots, reducing the burden of repetitive and potentially hazardous tasks on your team. This allows your workforce to focus on adding value in other areas of your production process. RARUK Automation offers tailored automation solutions, including UR cobots integrated with the Robotiq Machine Tending Solution, as well as robotic cells from EasyRobotics which are designed to seamlessly fit your existing setup. These systems are not only quick and easy to install but also deliver the fastest ROI in the industry. With lights-out operation, your business can maintain production around the clock, even after your employees leave for the day.